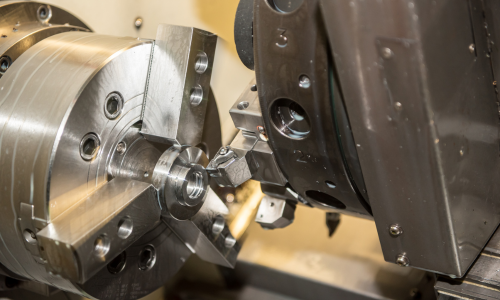

Gear turning is a machining process used to give shapes to gear forging by removing material from the outer diameter of a workpiece. This process is normally consist of two parts-rough turning and fine turning.

Rough turning is the initial stage of the turning process. The goal of rough turning is to remove the majority of the material efficiently, leaving behind a workpiece with a rough surface. After rough turning, the workpiece is closer to its final dimensions, and fine turning is performed to achieve the desired accuracy, surface finish, and tolerances.