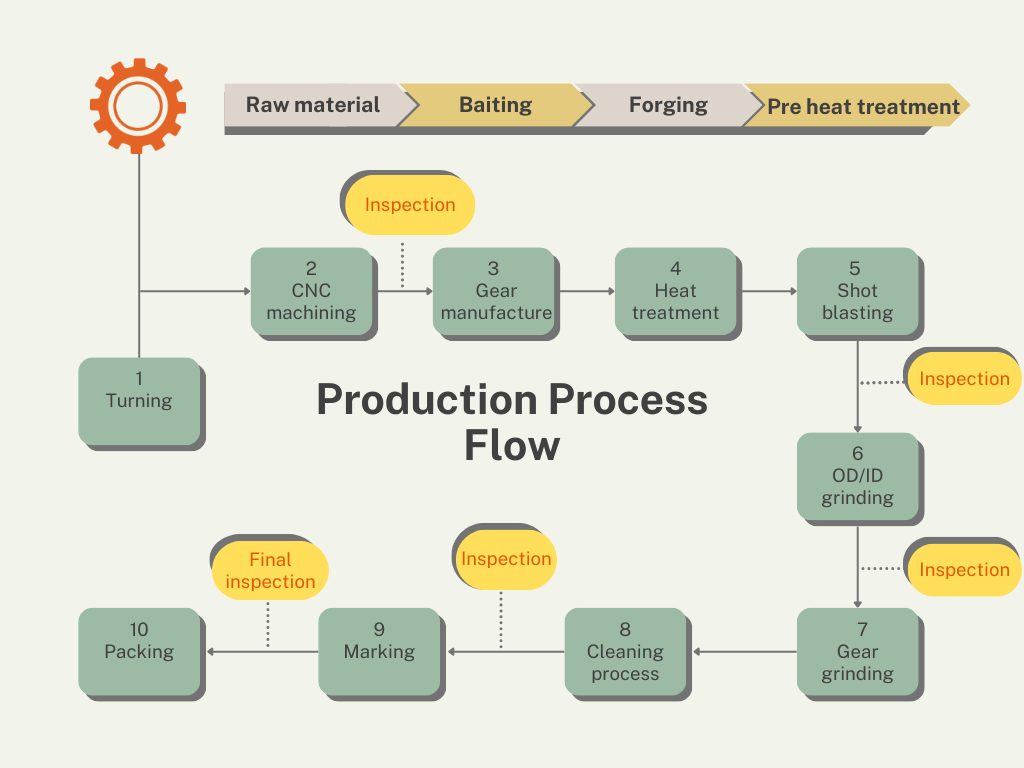

Dashmesh Gears are made with precision and are used in the most demanding applications. We continually invest in the best modern production equipment and ensure our raw materials are of the highest quality. All of our production stages are subjected to strict quality controls, so you can rely on us to provide your gearboxes and differentials with the highest performance operation and reliability.

Material inspection is the first and one of the most important steps for gear production. It involves a thorough assessment of the raw materials ensures that the selected materials meet specified standards and requirements.

At Dashmesh, Chemical composition, metallurgical properties, and physical characteristics are included in incoming material inspection.

Any discrepancies or deviations from the desired specifications are documented, and corrective measures are taken as necessary. Effective material inspection forms the foundation for producing high-quality gears with the desired mechanical properties for their intended applications.

At Dashmesh, we uphold a strict process control system. Our dedicated service support is your companion throughout the entire product lifecycle—from design and production post-sales service.

For Bevel Gears we check tooth contact in soft gears, topography inspection when required. Before Heat treatment dimensional Inspection of all machined parameters is ensured.

Heat treatment control is another critical steps that ensures our gear’s perfect performances. It refers to the systematic management and regulation of the heating and cooling steps to ensure gears meet desired standards of hardness, toughness, and durability.

It also involves careful monitoring of temperature, quenching rates, and other critical parameters, as well as adherence to strict safety protocols. Effective process control in gear heat treatment is essential for producing high-quality, reliable gears for industrial use at Dashmesh.

Final product inspection is the last critical step in ensuring the quality and integrity of Dashmesh gears.

This process involves a meticulous examination of completed gears to verify their adherence to specified standards and requirements.

For Bevel Gears Final Testing on Gleason tester to ensure backlash at a correct mounting distance, Tooth contact, and marking mounting distance adjustment if required.

We provide full sets of inspection report to customer before each shipment, which includes: