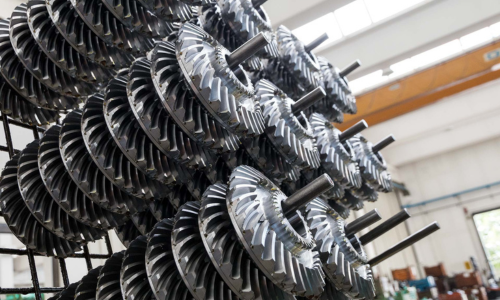

We are able to produce all kind of crown wheel pinion gears between 50 mm to 500 diameters. We use NC, conventional, CNC gear production machines and gear generators on our production. Our all crown wheel pinion gears have been paired on working conditions which supplied by the noise testing equipments. We have the ability to take a customer’s initial requirements, generate a concept and manage the process right through R&D, design, production and testing final delivery of a precision engineered, high performance, fully reliable, finished Crown Wheel and Pinions.

Heat treated gears are carefully grinded on CNC grinders and then profile grinded or lapped with special lapping liquid on GLEASON machines and are numbered. The products that are finally passed through quality control procedures are packed and shipped. Our firm focuses facility investments in the area of crown wheel pinion and bevel gear production machines and we're proud of our quality in the crown wheel and pinion gears we make.

For manufacture and finishing of Crown Wheel & pinion world renowned Gleason and Oerlikon Systems are installed.

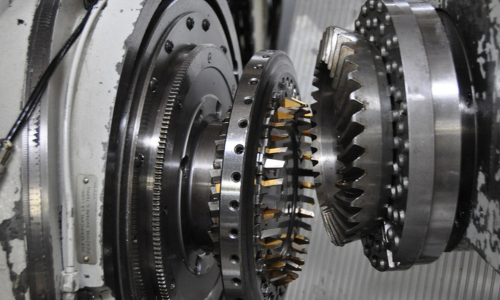

To complete finishing of bevel gears, we have the capability to perform running-in. This is carried out by engaging together (lapping) a pinion and a crown adding a fluid containing abrasive. Doing this, minor deformations of the heat treatment are corrected, positioning the contact in the position desired by the customer, and operating noise is reduced.

We are equipped with a "lapper" for running-in and a tester for subsequent checks. We produce bevel gears up to DIN2 standard quality, and we can include isotropic finishing process or highly performed coatings for more demanding requests. We have also already realized special gears that can achieve outstanding rotation regimes with great results in precision and resistance.