One of the last steps in the manufacturing process is grinding. This process is necessary to improve the finish as well as create the accurate size of the product.

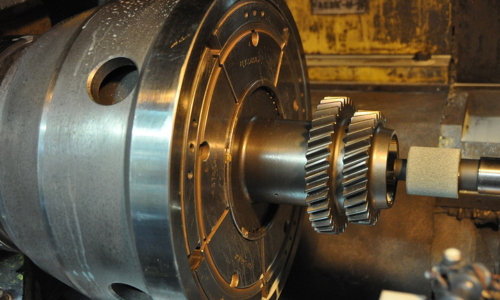

The external grinding is performed on planes and/or diameters, cylindrical or conical, to bring the surface of the heat-treated piece to an optimal state, both in geometric and roughness terms. This process is performed by the abrasion exerted by an extremely hard grinding wheel, generally fine-grained.

We are equipped with external adjustments and plane adjustments (parallel grinder polisher), with the ability to grind gears and shafts up to 300mm in diameter.

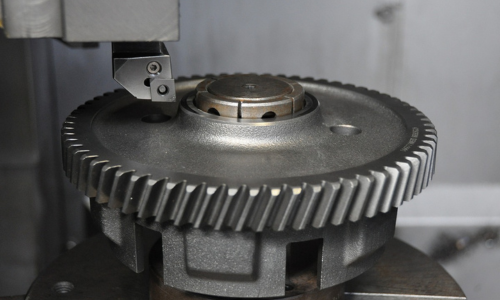

Internal grinding is performed on cylindrical or conical holes, to bring the surface of the heat-treated piece to an optimal state, both in geometric and roughness terms. This process is executed with the abrasion exerted by an extremely hard grinding wheel, generally fine-grained.

We are equipped with internal grinding machines to grind gears up to 300mm in internal diameter

We are equipped with internal grinding machines to grind gears up to 300mm in internal diameter

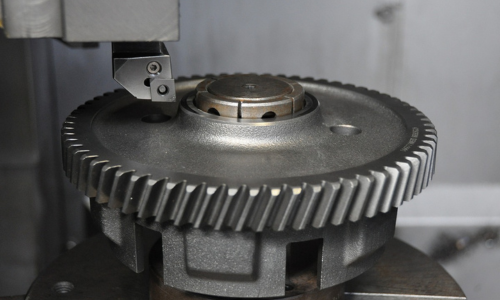

Hard turning is an alternative process to grinding one, when allowed by construction drawing, carried out on planes and/or diameters and holes, cylindrical or conical. This process brings the surface of the heat-treated piece to an optimal state in terms of both geometric and roughness. The processing is performed with dedicated and specific inserts.

We are equipped with CNC horizontal and vertical lathes, single spindle and twin spindle, capable of turning products with diameters and lengths up to 1000mm.