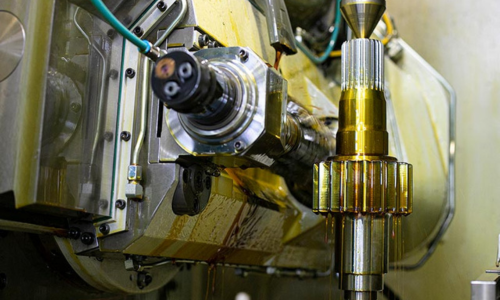

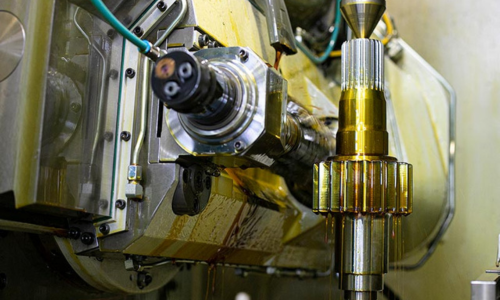

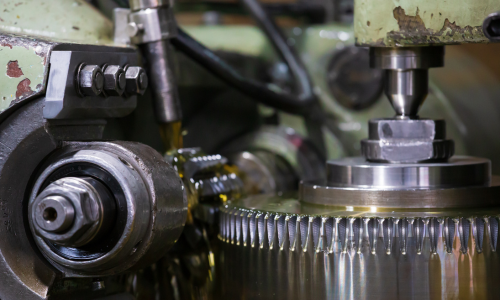

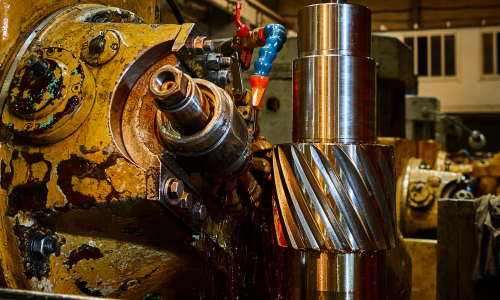

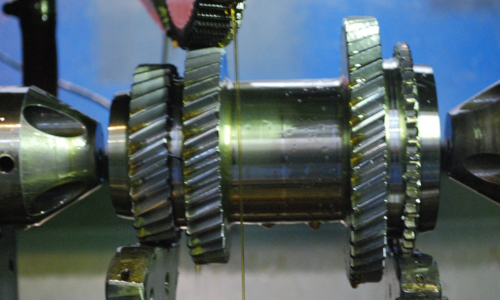

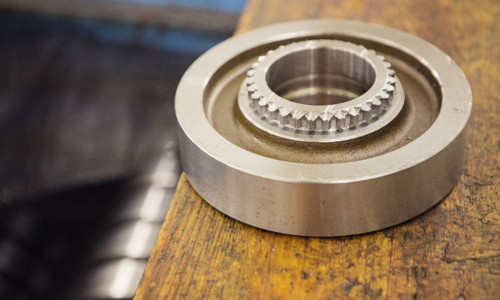

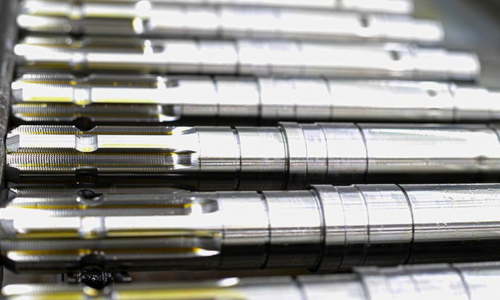

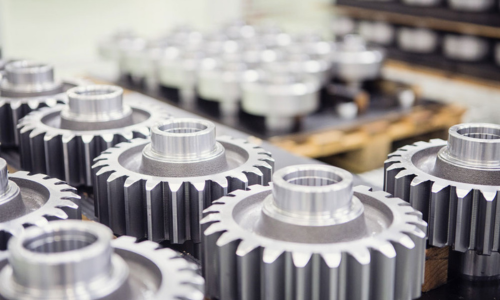

The cylindrical gear teeth processing is our core business. We have been supplying a wide range of spur gears, helical gears, gear shafts, ring gears and many more to various countries. As a matter of fact, significant investments have been made in this department over the past few years to improve its performance and make it high-tech.